A glass test cell that was fabricated to visualize noble gas behavior in a stagnant molten salt column. (Photo: ORNL)

Transparency is one advantage of certain molten salts that could serve as both a coolant and fuel carrier in an advanced reactor. For scientists studying molten salt chemistry and behavior at the laboratory scale, it helps if the test vessel is transparent too. Now, Oak Ridge National Laboratory has created a custom glass test cell with a 1-liter capacity to observe how gases move within a column of molten salt, the Department of Energy announced August 5.

A rendition of Terrestrial Energy’s IMSR. (Image: NRC)

The Canadian Nuclear Safety Commission (CNSC) has completed phase two of its prelicensing vendor design review for Terrestrial Energy’s Integral Molten Salt Reactor (IMSR), the Ontario-based advanced nuclear technology firm announced Tuesday. Phase one of the VDR commenced in April 2016 and was completed in November of the following year.

Researchers are looking for the ideal characteristics of molten salt, which can serve as both coolant and fuel in advanced nuclear reactors. (Photo: Argonne National Laboratory)

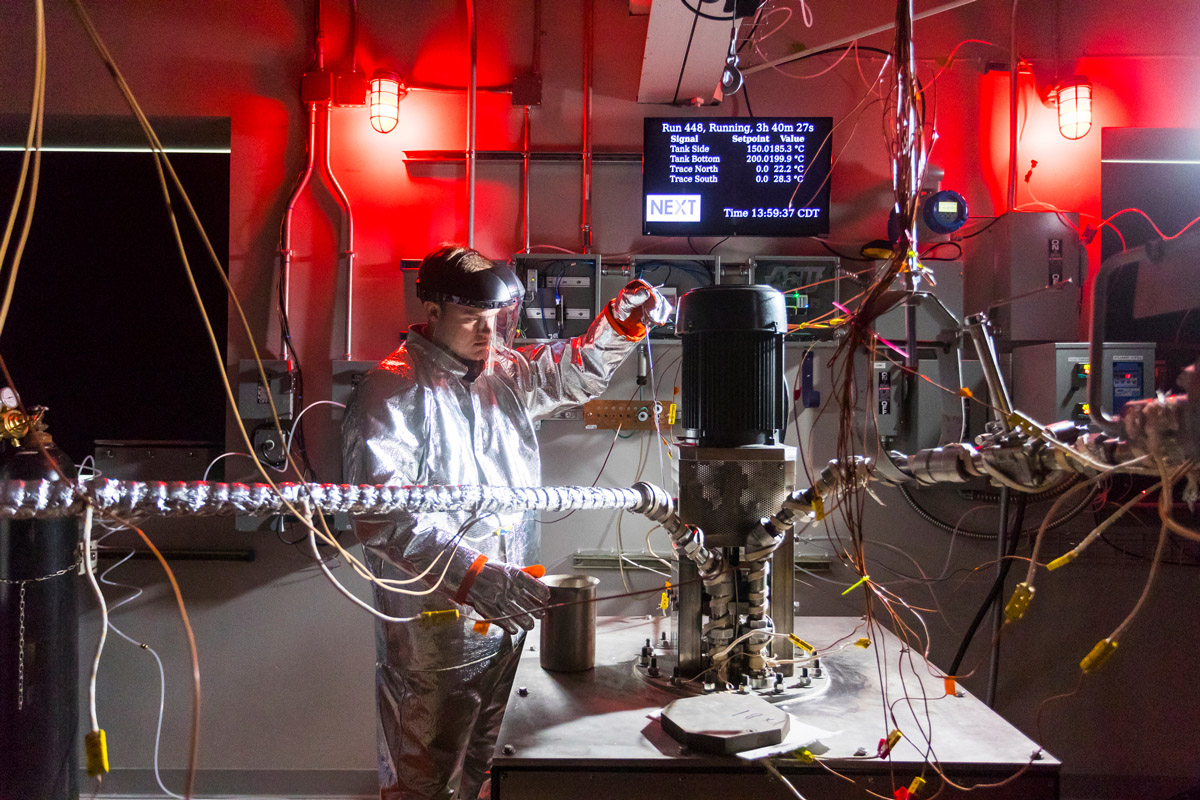

Scientists are searching for new materials to advance the next generation of nuclear power plants. In a recent study, researchers at the Department of Energy’s Argonne National Laboratory showed how artificial intelligence could help pinpoint the right types of molten salts, a key component for advanced nuclear reactors.

Building instrumentation and control technologies into the design of the next generation of advanced nuclear reactors will help the industry meet zero-carbon-emissions goals.

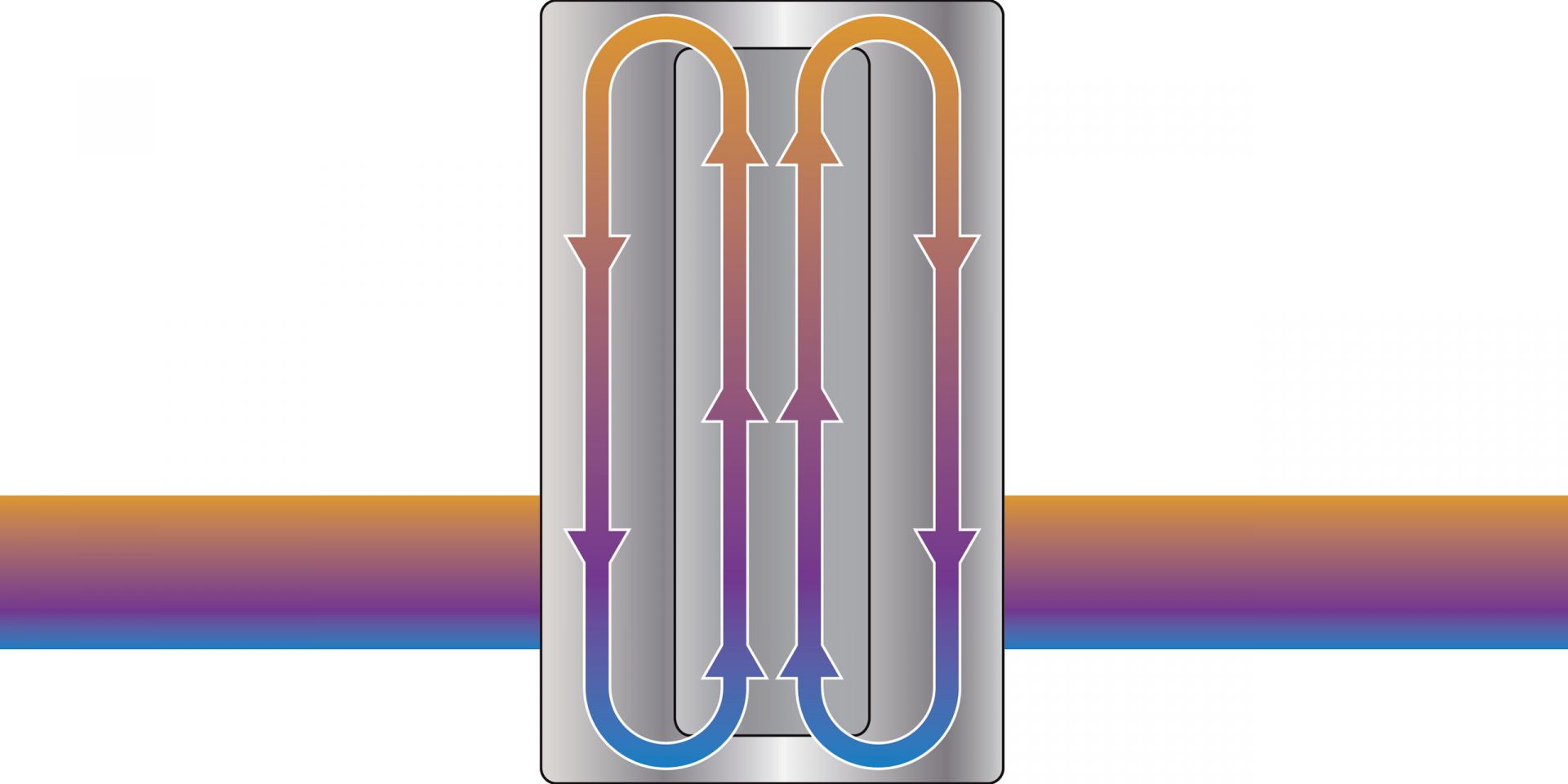

December 23, 2021, 3:00PMNuclear NewsAlexander Heifetz, Matthew Weathered, Nathan Hoyt, Mark Anderson, Scott Sanders, Anthonie Cilliers Kairos Power’s Instrumentation Test Unit

As a source of carbon-free electricity, nuclear energy currently dominates in the United States. However, the light water reactors in the U.S. are approaching the end of their licensed service lives. Meanwhile, low-cost electricity generated by fossil fuel–based sources (such as natural gas) poses an ongoing challenge to the economic viability of commercial nuclear reactors. To enhance the competitiveness of the nuclear industry, we need to bring down the high operating and maintenance (O&M) costs through savings available from utilizing modern, efficient sensing and automation technologies.

Artist’s rendering of the MMR project. (Image: USNC)

Global First Power’s (GFP) Micro Modular Reactor (MMR) project has moved to the formal license review phase with the Canadian Nuclear Safety Commission (CNSC), becoming the first small modular reactor to do so.